Production at GA Pet Food

Our state-of-the-art manufacturing site is home to one of the most technically advanced extrusion facilities in the world.

Our investment in the world’s first thermal twin extruder allows GA Pet Food to include extremely high levels of fresh meat in premium dry pet foods without the use of dry meat meals.

The improved palatability of a ‘Freshtrusion®’ diet is further enhanced by using our new vacuum coater to evenly distribute fats, oils, and palatants on and throughout each kibble.

With three extruders, GA Pet Food has a production capacity of 100,000 tonnes of super premium pet food and the ability to make batches from 5 tonnes to 200 tonnes to suit all partner’s needs. GA Pet Food delivers the same exceptional quality and consistency, no matter the batch size.

Innovation in action: The Wenger TT3630

GA Pet Food commissioned the world’s first Wenger TT3630 Thermal Twin extruder.

The Wenger TT3630 Thermal Twin extruder is unlike any other twin-screw extruder in use today. The Wenger TT3630 works in perfect harmony with the Wenger High-Intensity Pre-conditioner (HIP) in terms of design, capabilities, and efficiency.

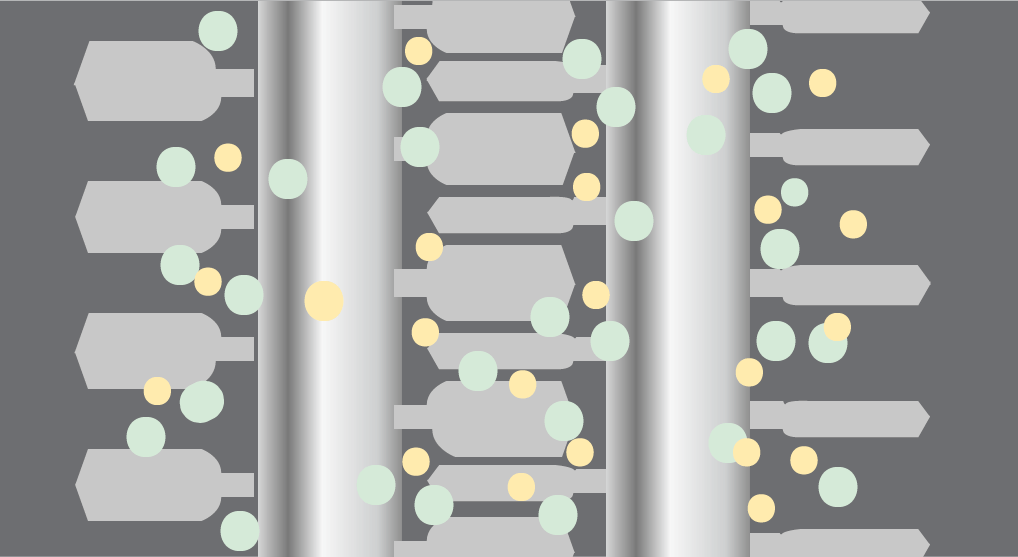

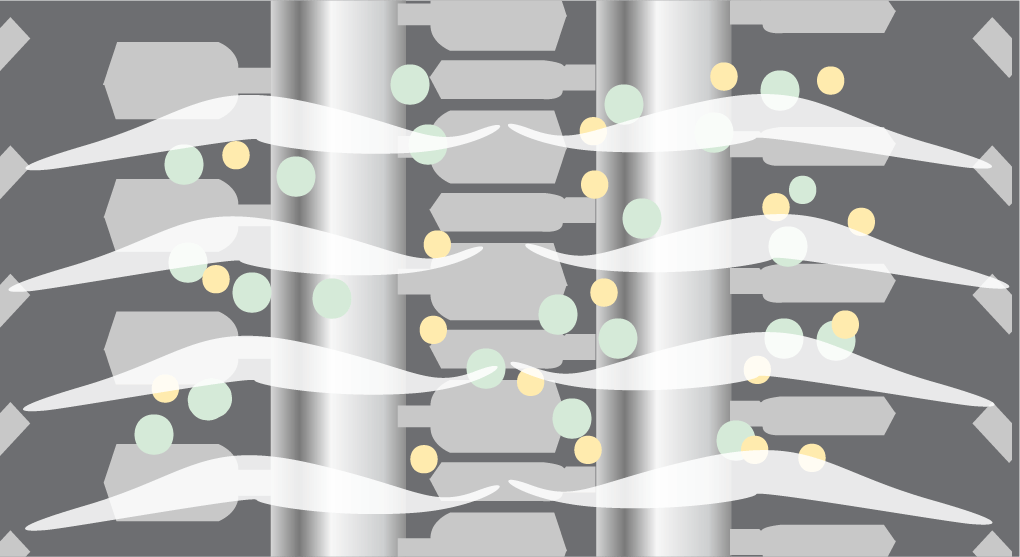

Ingredients are gently mixed in the HIP by two independently driven shafts, which allow steam to be ‘folded’ into the product. Angled steam injector ports in the extruder barrel orientated in the direction of material flow, along with a unique screw profile, allow further steam to be mixed into the product.

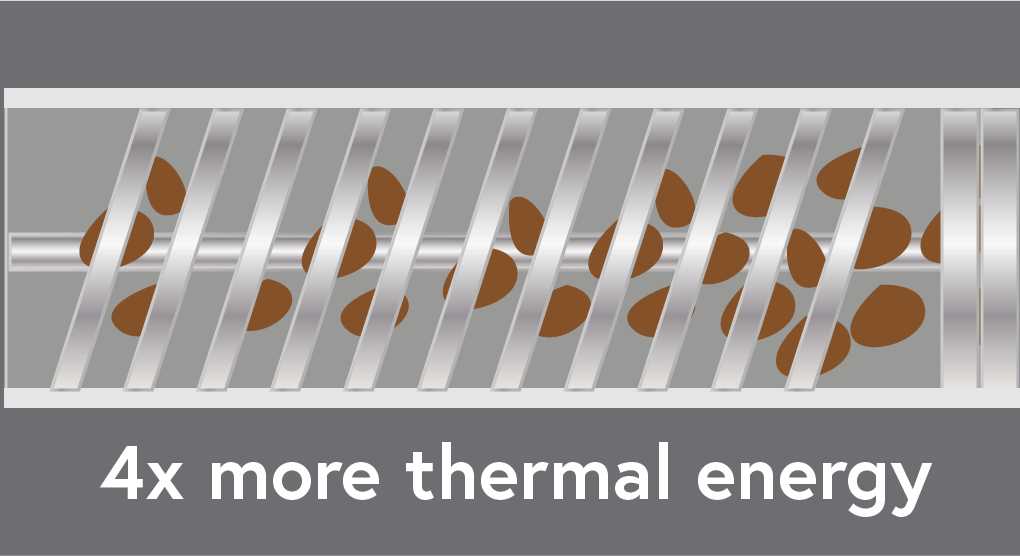

This means TT3630 can utilize up to four times more thermal energy and a half to one-quarter of the mechanical energy than other twin-screw machines. The reduced mechanical energy ensures a much less aggressive cooking process when compared to more traditional high sheer cook conventional extruders. This helps preserve the digestibility of proteins and the survival of the natural vitamins and minerals within the food whilst still achieving over 90% cook.

This new patented process also means we can process carbohydrates like potato or rice content without the stickiness previously encountered in other extruder designs. Starches may be fully cooked without damage to functional and organoleptic properties. However, the most exciting prospect is the ability to produce dry foods and treats with up to 70 per cent fresh meat.

The cooking process is completed with a unique 2 stage pre drier and secondary drying, which enables us to remove the high levels of moisture present in High Fresh Meat Kibbles and a vacuum coating system, which delivers unparalleled consistency when applying fats and oils post extrusion.

All this means that GA Pet Food has one of the most advanced production facilities in the world for the production of dry pet foods.

How does it work?

Ingredients are gently mixed in the High-Intensity Pre-Conditioner by two independently driven shafts, which allows steam to be ‘folded’ into the product.

Angled steam ports in the extruder barrel orientated in the direction of the material flow, along with a unique screw profile, allow further steam to be mixed in.

Using 4x more thermal energy and a half to one-quarter of the mechanical energy of other twin-screw machines, a much less aggressive cooking process preserves the digestibility of proteins.

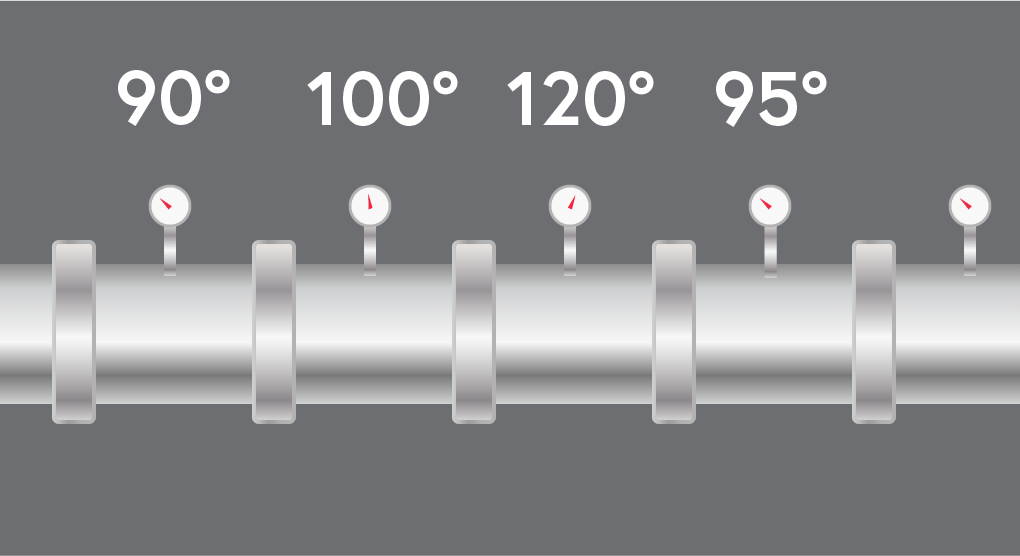

We can independently control the temperature of each section, allowing us to perfect the bespoke cooking process of our recipes.

Packing at GA Pet Food

At GA Pet Food, we continue to invest in our packing teams and automated machinery. We are proud of our multicultural, talented, experienced, and committed teams, and we are also excited by our state-of-the-art machinery. In addition, we work tirelessly to improve our processes to benefit our valued partner brands.

Equipment

Our nine packing lines package a range of products ranging from 50 g to 25 kg. Each packing line has a computer that informs the Line Leader of the current and subsequent productions, providing complete details of the product, packaging, and stacking requirements. Each production run has its own unique works order traced by RFID (Radio Frequency Identification), preventing any unforeseen human error and offering full traceability for the partner.

Before the line is run, the Line Operator checks the product is correct as per the specification, using a reference photo on the screen. Should the product not be to the exact standard, it is rejected, and a quality investigation commences. The bags are also placed horizontally into the machine and passed through a camera that checks the imagery of the bag, confirming it is correct.

Laser Coding

Next, the bags are laser coded prior to filling. Various information is etched onto the bag in exactly the same place every time, offering a guarantee that nothing will be missing or unreadable.

Weighing System and Quality Control

Meanwhile, the product is fed onto a weighing system into an arrangement of small buckets. After the weighing system has calculated the desired weight, it releases a number of buckets, dispensing the desired weight. Should the machine calculate an incorrect weight, a bypass system operates, and the product is diverted away from the filling tube. If the weight is correct, the product travels down a feeding tube and, on its journey, will pass through a metal detector.

Should the machine detect a foreign object, it will sound an alarm, and a quality system process will begin an investigation into the source of the object. Once removed, the machine will restart, and filling will resume.

Sealing the Bag

The bag travels past a thermal camera, which is used to guarantee the bag has been sealed. The camera uses thermal imagery to inspect the seal integrity. If the bag seal is faulty, the machine automatically rejects the bag, removing it from the process.

Online Weight Checking System

Every bag passes across an online weight checking system that weighs every single bag, guaranteeing the weight. The same system will automatically reject any bag found to be under or overweight.

X-Ray System

The bag travels through an X-ray system to check for metal or foreign bodies. In addition, every bag is photographed for reference, and anything detected will result in the bag being automatically rejected, with a full investigation taking place.

Automation

The bag enters a fully automated baling machine that will first index the bags to the partner’s requirement, for example, 2 × 2. Once indexing is complete, the bundle will move forward and become vertically wrapped in stretch film before going through the same process to be horizontally wrapped. This is so the bundle is fully encased, secure, and protected.

As the completed bundle exits the baling machine, it passes an automatic bale label applicator that places the partner label onto the outside of the bundle. The data on the label is automatically generated by the main control computer, eliminating any potential human error. The bags are then fed into the automated palletiser machine. This huge machine will perform a variety of functions resulting in a completed pallet at the end of the process. Finally, we automatically apply a label to the pallet. Whilst this is done, the roller conveyor the pallet stands on records the weight of the pallet. The pallet is now taken to our storage facility, ready for the partner to order.